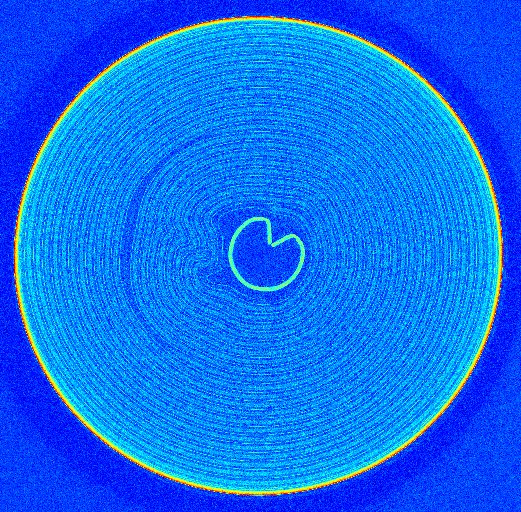

Our state-of-the-art X-ray computed tomography system allows for 3-dimensional in-situ imaging of complete battery packs, by assessing the uniformity and positioning of internal components crucial for overall performance. The Pattern-Recognition/Machine-Learning modules enable classifying—

Inner’s solution for you

and detecting faults down to 50µm, in existing and future chemistry and cell type formations. Additionally, our technology will provide the largest global EV battery database allowing for long-term analysis of degradation patterns and irregularity patterns of o improve the design of batteries.

Scenarios

For automakers

-

Leveraging our X-ray computed tomography system, automakers can perform comprehensive inspections at the end of the pack assembly line, to detect tears in wiring and bonding internal defects, misalignments, or structural anomalies, improve quality assurance processes. All without dismantling the battery pack.

-

A few layers of inspection: Safety and integrity; Internal formation; precise identification and analysis of faults and their location; A calculated recommendation enabling an informed Safety/Reuse/Recycle decision.

-

In many occasions, battery packs recalls are published on the grounds of physical deformation. In such cases, there is limited ability to actually determine if a specific pack "suffers" from the said fault, and the whole batch is excluded and recycled. With INNER's CT, automakers can inspect each pack to validate the existence of the fault or the lack thereof, to enable the continuation of the use of the pack.

For Recyclers

Scenarios

-

In order to receive incoming packs in an unknown state of health and integrity, there should be safety screening at the gate of the facility, before discharge takes place, by detecting potential hazards within batteries, such as internal damage or thermal runaway risks, our technology helps recyclers implement targeted safety protocols, reducing the risk of fires during the recycling process.

-

Leveraging our system, recyclers can easily visualize the internal setting and formation of the modules and all of the other components of the pack, without opening it. This way, there will be no need to use sketches of the pack's internal structure.

-

Our X-ray technology enables precise identification and analysis, of various battery faults, including cracks, swellings, deformations. This improves recycling efficiency and ensures proper handling of different battery chemistries, while maintaining high-quality output for downstream processes. With precise identification of the fault detected and its location, one can make an better informed reuse/recycle decision.

For BESS (Battery Energy storage systems) Builders

Scenarios

-

Leveraging our X-ray computed tomography system, BESS builders can perform comprehensive inspections at the end of the pack assembly line, to detect tears in wiring and bonding internal defects, misalignments, or structural anomalies, improve quality assurance processes. All without dismantling the battery pack.

-

Our CT scan and AI analysis system is crucial for BESS builders repurposing EV batteries. It provides detailed internal imaging of complete battery packs, detecting structural anomalies or hidden defects. This ensures only safe, structurally sound batteries are integrated into second-life storage systems, enhancing reliability and safety at the gate

-

Our CT scan machine with AI analysis revolutionizes BESS maintenance. It provides comprehensive, non-invasive inspection of entire battery packs, detecting potential faults before they escalate. This minimizes downtime, and ensures overall optimal performance. Invest in our technology to enhance reliability, reduce maintenance costs, and maximize the efficiency of your projects.

Cell Producers

Scenarios

-

Our technology provides cell producers access to the largest global database of EV battery cells and packs images - taken from the battery pack level.

This enables for a unique, long term ongoing tracking and monitoring analysis of the cells and modules to identify unknown patterns: uniformity, positioning of internal components, degradation and irregularities to facilitate improvement of the cell and pack design.

.

Integration of Our Tech to Your Workflow

Our end to end scanning and processing takes minutes. By integrating our technology into your existing workflow, we adapt to your processes and without any disruption we ensure scans while creating an automated report and actionable recommendations immediately after. Our solution is designed to streamline operations, saving time while enhancing accuracy and efficiency.

Complete Diagnostics Report

Based on the images and analysis, we will promptly provide a comprehensive verbal and graphic report, outlining recommended uses, safety considerations, and possible options recommended.

1. High Level Overview Analysis

This section includes the final evaluation if the pack is ‘Safe’ or ‘Unsafe’ to process.

2. Detailed Analysis:

The ‘List of Fault’s’ Report details the specific physical deformations found and their location.

4: Assessment and Recommendation:

Analysis of the found faults and a calculated recommendation enabling an informed safety/reuse/recycle decision.

The end to end scan and analysis will take minutes. As our technology is complementary for State of Health (SoH) and State of Charge (SoC) analyses, we are working to integrate these testing within the overview and provide a one-stop-shop for a complete comprehensive diagnosis.

3. Internal Formation:

This section includes an overview of the internal formation of the modules inside the pack, and suspected locations of a fault.

Available now:

Send us your packs for diagnosis!

If you're looking to inspect and validate the integrity of your battery packs (new or old) for any signs of physical deformation, we’re here to help!

Don't leave your battery reliability to chance—contact us today and take advantage of our beta testing services offered in collaboration with Fraunhofer EZRT.

Book a Demo

Schedule your demo now and take the first step towards a safer, more profitable and sustainable world.